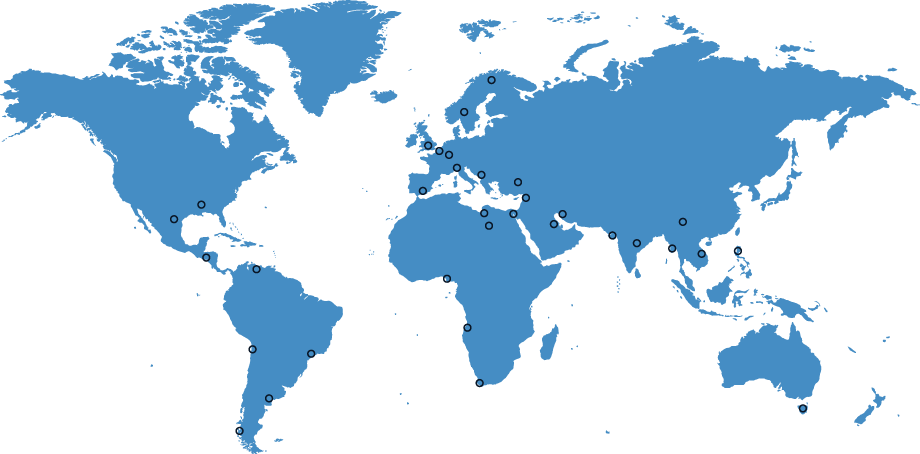

LOECO GmbH was founded 40 years ago to engineer, manufacture and supply turnkey industrial plants. The company has supplied its products to plants located in many countries around the world. LOECO is upholding and advancing the standards of quality established by its founders. The most advanced manufacturing techniques and highest quality materials are utilized to ensure uncompromising parts and performance. LOECO is committed to being in the fore-front of its industry with leading edge engineering technology and quality control second to none. The company has supplied its products to plants located in many countries around the world.

Due to its many advantages, the hot dip galvanizing process ranks first amongst the various surface protection processes, especially as far as tubes are concerned.

Experience of long-standing and the supply of more than 100 galvanizing plants to numerous countries around the world, guarantee the best know-how and engineering. We design and supply hot dip galvanizing plants of all kinds for structural parts and bulk goods and in particular for pipes and tubes.

This new type of galvanizing plant transports the pipes individually through the pickling line. The complete transport from the pipe feeding station through the ➜ degreasing ➜ rinsing ➜ pickling ➜ rinsing ➜ fluxing ➜ drying ➜ galvanizing ➜ blowing off ➜ blowing out and ➜ cooling to the ➜ pipe collection pit …is fully automatic!!

• This plant can operate directly „in-line“ with a pipe manufacturing line.

• Round pipes as well as square and rectangular tubes can be galvanized.

• This new plant concept guarantees optimal control of the zinc coating thickness.